Surefoot vs Screwpiles

March 29, 2019 // BMSA Footing Solutions

|

|

How does a Screw pile or Helical pile system work?

Screw piles or helical anchors are a steel screw-in piling system that are anchored into the ground vertically. The pitch of the helices on the steel tubes determines how they will perform in certain soils.

Soil types

The Surefoot footings are design engineered specific to the soil conditions of each site. Watch this video to see the principle at work and how easy it is to install Surefoot footings – just 10 minutes per footing.

Surefoots’ distinct competitive advantage is its embedment into any soil type with load bearing capacity of 100kPa. To ensure the 100kPa load bearing, the soil report informs at what depth to find that kPa reading which enables BMSA to provide a fixed quote.

Screw piles on the other hand are also designed to suit the specific soil, but they need to be installed in soils that do not have gravel or cobble otherwise the helices do not advance correctly into the coarse material.

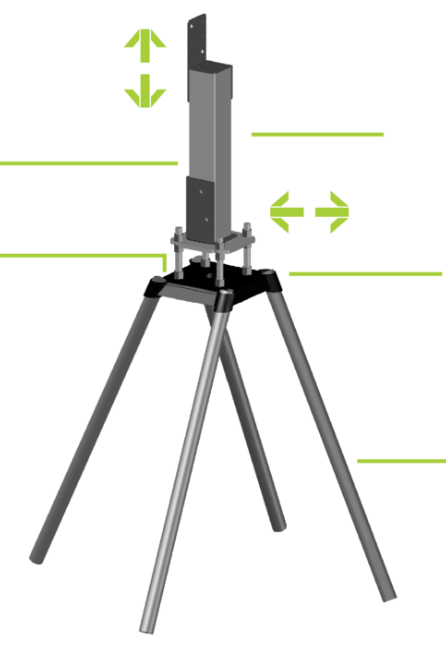

Alignment

Surefoot footings are easily installed and aligned both vertically and to agreed heights. Screw piles can deflect off floating rocks resulting in misaligned and out of plumb stumps.

Installation equipment

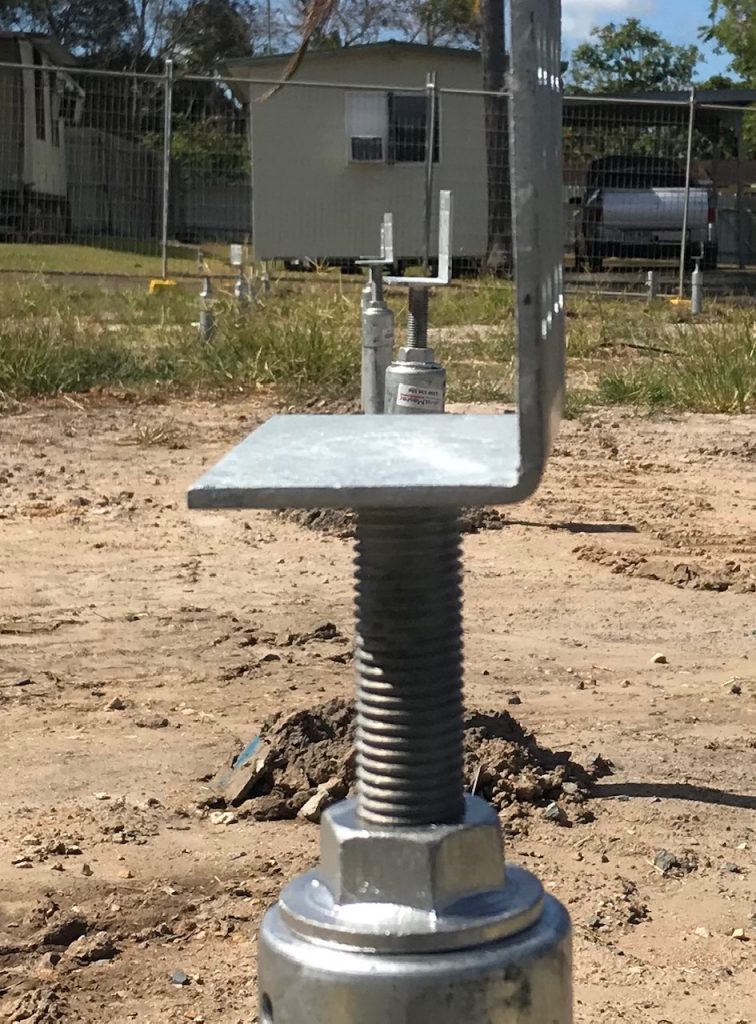

Surefoot footings minimise soil disruption. A jackhammer is all that is needed to install them correctly and one person can do the installation.

With Screw piles, soil displacement up to 750 mm at the surface can result in lateral movement with soil tending to be disturbed along the full length of the pile which can result in weakness within the soil strata. To attain design depth for a screw pile, heavy torque machinery on excavators is required to drive the piles vertically into the soil. This is not always practical in confined spaces with no access. Surefoot uses hand held machinery to install the piles to anchor the Surefoot footings.

Clean up

Being a minimalist anchoring solution, post project clean-ups are a significant advantage of the Surefoot system. No heavy equipment is required, no deep tracks are incurred, and efficiency of completion is a standout benefit.

Price advantage

When you approach BMSA for your footing solution, you will get a fixed price quote based on your building plans and the site’s soil report. The only potential variation is if the soil conditions are not as per the soil report.

Companies installing the screw pile system cannot give you a definite price upfront as extra depth may be needed if the required torque settings are not achieved. Installation to specified torque settings can stress welded joints and stretch the steel to a possible point of failure.