Market Leading, Concrete Free, Foundation Systems

RapidStump, Advancing Australia’s Concrete Free Steel Footing Industry

RapidStump Engineering Principles

RapidStump engineering principles are based on piling technology using a combination of skin friction and bearing to achieve load abilities in various soil types.

Design capacity calculations are based on the working stress method, using refined geotechnical data, obtained throughout time for skin friction and bearing pressure.

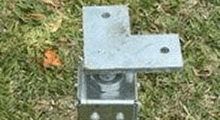

RapidStump System

The unique RapidStump design creates a footing and stump all in one system. Once piles are secured to the sleeves, the opposing forces of the multidirectional piles provide a solid, stable, and economical foundation. The system is designed to increase its efficiency when resisting gravity, uplift, shear, and moment loads. Ultimately the soil structure absorbs the applied stress.

BMSA’s, RapidStump system is job-specific and is designed according to site soil conditions and structural design loads.

Prices start from $122.00 + GST